- CTP wastewater treatment equipment

- Light guide plate equipment

- Automatic Sticker Machine

- Non - Standard Automation Equipment

- Connector Industry Automation Equipment

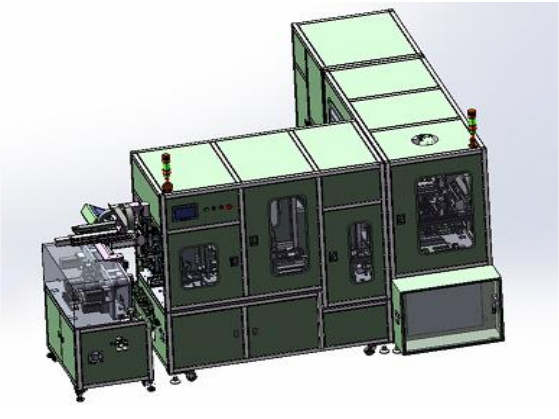

- Fully Automated Production Lines

- Test Fixture Series

- Tooling Carrier Series

- The first division (standard machine)

Contact information

DongGuan MSA Intellingent Technology Co.,LTD

Contact: Mr. Cai

Mobile:13650018949

Contact: Mr. Zhang

Mobile:13809627148

Tel:0769-81111739

Fax:0769-81621070

E-mail:msamg@msasmart.com

Website:m.aqnjfqm.cn

Add:1st Floor, Yunding Technology Innovation Park, No. 22, Farm Industry Road, Dalingshan Town, Dongguan City

NTC (Negative Temperature Coefficient) is a negative temperature coefficient thermistor, which uses metal oxides such as manganese, cobalt, nickel and copper as the main materials and is manufactured by ceramic technology. As the temperature increases, the number of carriers increases, so the resistance value decreases. The variation range of NTC thermistor at room temperature is 100~1000000 ohms, and the temperature coefficient is -2%~-6.5%. Widely used in temperature measurement, temperature control, temperature compensation, etc. (electronic thermometers, electronic calendars, electronic clock displays, electronic gifts; heating and cooling equipment, heating thermostat appliances; automotive electronic temperature measurement and control circuits; temperature sensors, temperature meters; medical electronic equipment, Electronic toilet equipment; mobile phone batteries and rechargeable appliances.

However, due to the limitations of automation technology and processing requirements, the labor efficiency is low, the requirements for skilled hands are high, the recruitment is difficult, the retention is difficult, the quality stability is poor, the defect rate is high, and the wages and benefits of personnel continue to increase, and customers are increasingly concerned about the delivery time and quality. Gaogao still uses pure manual kneading, manual feeding, and manual tin immersion. Today, it is no longer enough.....

Based on the above factory pain points, Haiyi Technology hired foreign professors and engineers to jointly develop a fully automatic NTC automatic welding machine in 2018. After 3 years, with the efforts and efforts of all partners, it has successfully developed and obtained inventions and new utility patents. Instead of manual operations, it greatly improves efficiency, saves manpower for the factory, and ensures the consistency of quality and reduces the defect rate.

1. Structure highlights:

(1) The frame is made of the national standard square pass combined with gantry milling to ensure the stability of the frame while ensuring the level and verticality of the component installation.

(2) The design is simple and practical, which can quickly master the adjustment and change the product model.

(3) Fully consider the compatibility of the length of the wire, which can be quickly replaced, and each module adopts a fool-proof design.

(4) The mechanism window adopts translucent brown PC, high-end atmosphere and convenient to monitor internal working conditions.

(5) Modules and well-known brand pneumatic accessories are combined with soft software, and are characterized by strong versatility in feeding, temperature control accuracy and stability, large subsequent expansion space, high repeatability, and good welding quality.

(6) The tin furnace bladder is made of 316 material with titanium infiltration treatment, which is durable.

(7) CCD (automatic vision) inspection is used to screen defective products and automatically remove them.

2. Electronic control (software) highlights:

(1) Using Panasonic PLC, the program runs stably and at the same time reserves upgrade space for the subsequent expansion of functions.

(2) The circuit of the whole machine provides various protection functions: such as leakage protection, undervoltage protection, external interference filtering, overvoltage and overcurrent protection, etc., which not only protects the safety of personnel, but also fully protects the machine itself.

(3) In terms of software parameter design, various complicated situations have been fully considered, from external communication to internal control. Set up a variety of flexible and reliable parameter settings, and simple, easy to adjust and understand.

(4) The system also has two modes, automatic and manual, which reduces human errors while improving the function.

(5) In terms of line wiring, line management, etc., fully consider the strong and weak current management to ensure electrical safety, stability, and reliability.

(6) Equipped with an error information self-correction diagnosis system, which can self-diagnose the faults during the operation of the equipment, eliminate the faults, and resume production in time.

(7) The life management and monitoring of the stripping tool is to prevent the tool life from exceeding the standard, which will affect the poor wire stripping and lead to a large amount of waste.

(8) Modular control system, with extremely high stability, adopts patented technology for wire correction accuracy up to 0.02mm tolerance, meets wire welding requirements and guarantees welding quality. Modular electronic control system, fast troubleshooting, convenient for maintenance and upgrade of equipment later.

(9) Patented cable management technology, extremely low space occupancy and strong stability, fast and high-precision CAI cutting, peeling, tinning, NTC automatic feeding, automatic assembly, flue coating, automatic detection.